Moving slowly towards completion.

I'm still chipping away at little jobs but money is still the biggest obstacle. I was made redundant in March due to my knee injury and the kind people at the DWP have offered me zip! So I'm just getting a few bits here and there as I can afford them. It does mean that updates are likely to be few and far between though.

Still there has been progress since I last updated the blog. If you follow the facebook page then you will already have seen the progress but if not I hope you like it.

Firstly I got the front wheel on and bought an Acerbis front mudguard as it's a bit more aggressive looking. However I'm not convinced it will clear the exhaust so I might be returning to the original type.

Next stop was the rear wheel and what a jolly time I had trying to wrestle that into place. The paddock stand I have is too wide even on its narrowest setting to be able to keep the bike off the floor, so I was trying to keep the bike up while lining the wheel up and getting the spacers in and then put the spindle through the lot all with a still wonky knee. If it wasn't difficult there would be no fun trying eh?

As you can see the tank is black too but I wasn't happy with the paint as it stayed soft for a very long time after painting and when I spilt some petrol on it it ruined the finish so I'm having to redo it. The back wheel, seat and rear panel are all in place even though the rear panel isn't painted yet. Red low riser bars are in place but I don't think they look right so I'll be going back to high risers at some point. The rear shock are upside down too. After all my work refinishing them I tried to fit them only to find that the reason they were in such bad shape in the first place is because they were bodged to fit and probably hammered into place, so they are just fitted that way to keep the bike up while I do stuff to it.

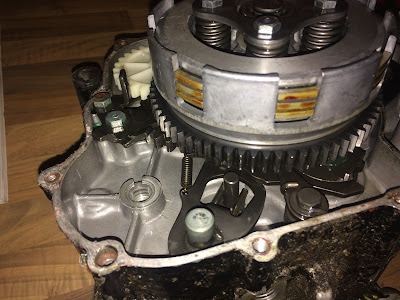

I have now put the engine into the frame but without the cylinder and head as they are yet to be purchased. The wiring has mostly been connected and a new rear light has been fitted. I ordered stainless steel bolts to mount the engine as I want the bike to look as new as possible for as long as possible.

I had a small headache with the clutch cable today trying to figure out how best to route the cable without it getting pinched in the steering stops or move out on the right side of the bike when the steering is turned to the right. I think the cable is a couple of inches too long which is making thing more difficult. I ended up zip tying the cable to a part of the frame that allows it to move around without looking silly. You can see in the picture above that the front mudguard has a more aggressive look but the bars look too low. The tank is primed and ready for the top coat. I painted the rear panel with some paint from euro car parts (rattle can), and its given a nice finish. I have tested a small area with petrol and it didn't soften run or peel so I'm definitely going to use that stuff on the tank.

Overall I am very happy with it and it's coming along very nicely compared to the old ratty red monstrosity it was just 7 months ago. Now I need the wife to give me some pocket money so I can get it finished. Time to cash in those brownie points!

I was contacted yesterday by a guy called Tim Dickson from Practical Sportsbikes magazine who wanted some details about the bike for an article he's writing. Hopefully my little project will appear in the next issue.